One of the most common questions we get at Alamtal Flooring is what the difference is between epoxy floor coating and polyaspartic floor coating. These coatings may look similar, but some significant differences between the two products may persuade you to choose one over the other when it’s time to protect your concrete floor.

Here’s a look at the advantages and disadvantages of epoxy flooring and polyaspartic floor coating. Alamtal Flooring can help you choose the right product for your garage or basement floor.

Epoxy Floor Coating Pros and Cons

Epoxy floor coating has been on the market for a number of years. It is relatively inexpensive and provides a durable, beautiful finish to unfinished concrete. Epoxy floor coating adheres well to concrete and is easy to apply. In fact, some homeowners choose to DIY their epoxy floor coatings. Epoxy coating is available in a wide variety of finishes to complement any design style.

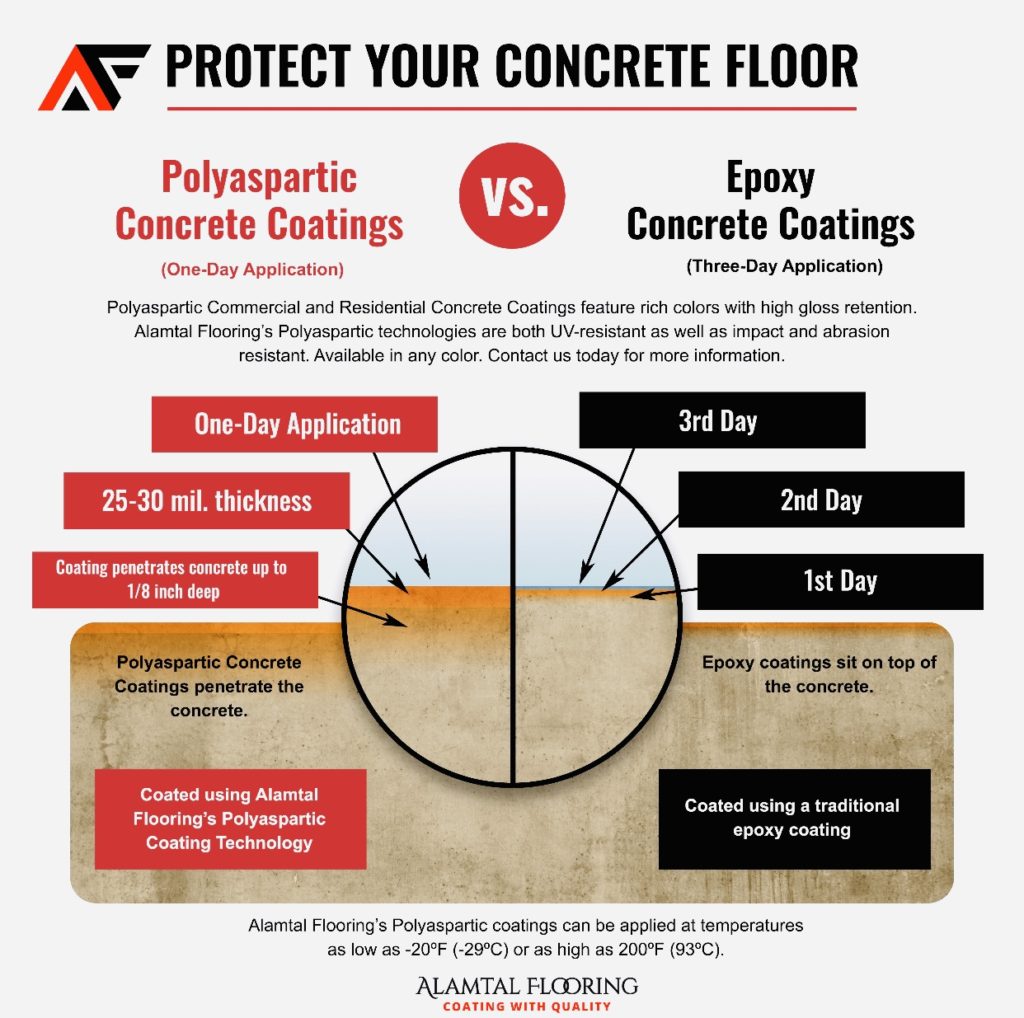

So, what’s not to love about epoxy floor coating? Every layer of epoxy coating takes at least a day to dry. Most applications require multiple coats, so the entire project may take three days to apply, then another three days to dry completely before you can walk or drive on the floor. Epoxy is sensitive to temperature and cannot be applied when temperatures dip below freezing.

What’s more, while epoxy floor coating creates a hard surface, this makes it susceptible to abrasion, as it cannot flex. Its color can also fade in sunlight. Plus, it’s stinky stuff. Older versions of epoxy flooring contain potentially hazardous VOCs.

Polyaspartic Floor Coating Pros and Cons

Polyaspartic floor coating is a relatively new product that is challenging epoxy’s dominance in the concrete floor coating market. Polyaspartic floor coating can cure in as little as five minutes and driven on in just 24 hours. It can be installed in freezing temperatures. Like epoxy floor coating, it creates a durable, beautiful surface. But unlike epoxy flooring, which sits on top of the concrete, polyaspartic coating penetrates the concrete to create an impermeable bond. This creates a stain-resistant, fade-resistant, abrasion-resistant, and bubble-free surface you can enjoy for years. Plus, it’s low/no VOC, so no stink.

While it has numerous advantages over epoxy floor coating, polyaspartic coating does have some minor drawbacks. Because it cures so rapidly, polyaspartic coating leaves little room for error. It must be installed by a professional installer like Alamtal Flooring. We work in teams of two to three to get the timing right, which is tough for DIYers working on their own. Like all floors, polyaspartic floor coating can be slippery when wet, but adding chips or flakes can create good traction. Alamtal Flooring also adds anti-slip grit to minimize any slipperiness. The coating also does not stand up to battery acids as well as epoxy flooring does. If you’re worried about battery acid spilling on your floor, we recommend you place a protective covering over your floor before you begin work.

Once homeowners understand these potential drawbacks, many still feel polyaspartic floor coating is a clear winner over epoxy. It cures faster than epoxy, smells less during application, and creates a durable surface that will last years. Most drawbacks can be avoided by hiring a professional team to install your floor and using preventative measures to protect it.

Ready to learn more about your concrete floor coating options? Call or contact us today to get a free quote on your flooring project and get on our schedule.